Lathe Page 2

the acme pitch is Imperial , you'll select the correct thread change gears for this operation 65 teeth for the top gear, the next gear is the 95 tooth, then the 55 tooth and finally the 57 tooth gear. DP is diametrical pitch, you probably not be using those unless you are cutting worm gears on the lathe.

Information Chart for Threading on a Lathe.....

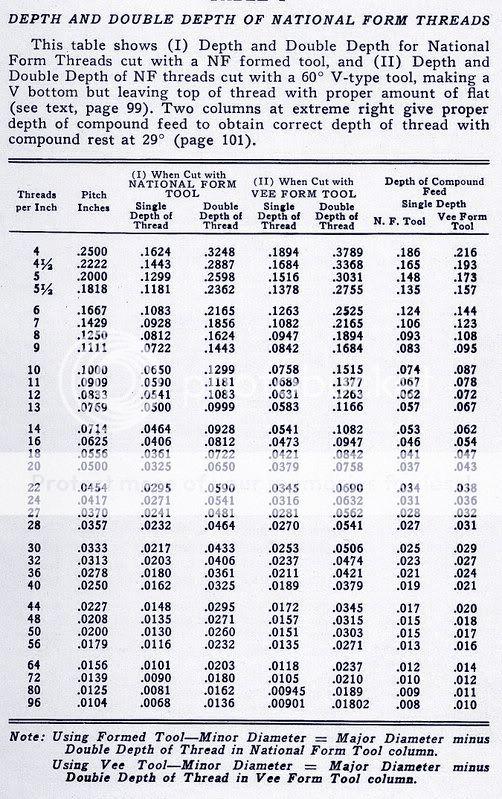

When the tool clears the thread, shut off the lathe. Return the tool to the correct cutting depth plus the cutting increment and make another pass in the forward direction.. On the back of the gage is usually a chart of threading depths for inch threads, not terribly useful for this discussion. The gage is typically used like this, though a.

Lathe Thread Cutting Chart Depth of Compound for SAE Threads 3" eBay

Thread forming is not considered. For forms, calculate values with a factor of 1.7. Thread depth [mm] x Hint: The appropriate depth of thread in your machining. Cutting speed [m/min] x Hint: The cutting speed depends on the composition and strength of the material and the tool material used. Speed [rpm] x Hint: Rotation on the spindle. Pitch.

Full Norton lathe machine thread chart example YouTube

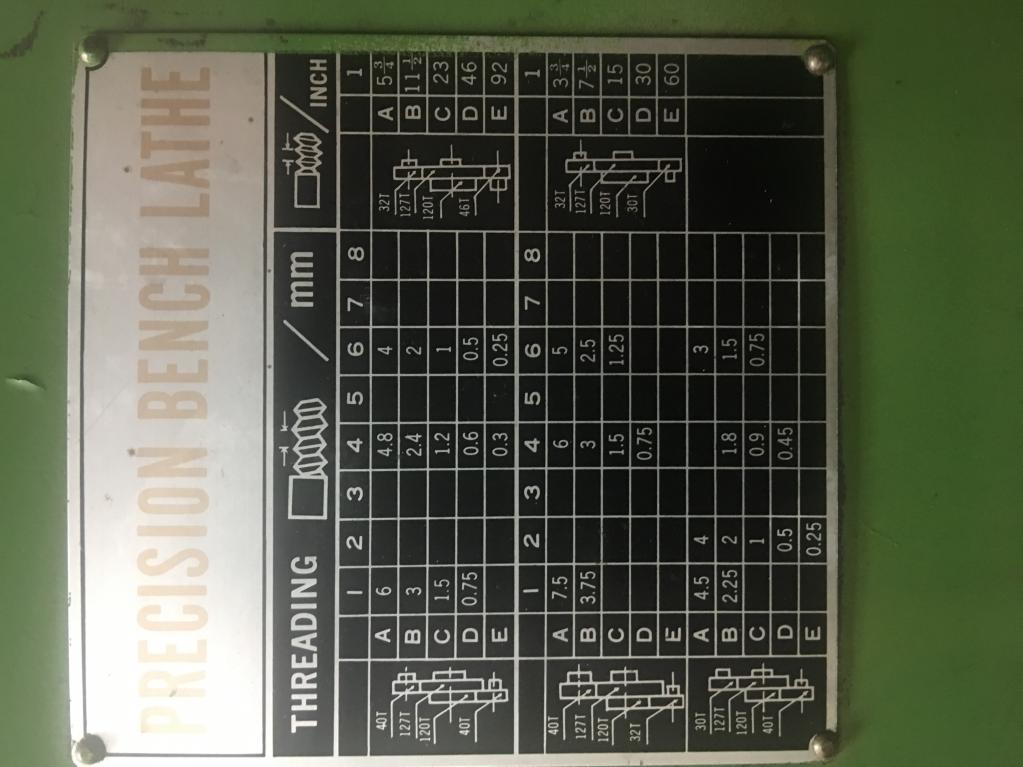

Change Gear Calculator Make the choices to define your lathe below before calculating a thread pitch. This calculator determines the correct change gears for any thread pitch. Works for all mini lathes and HiTorque Bench Lathes.

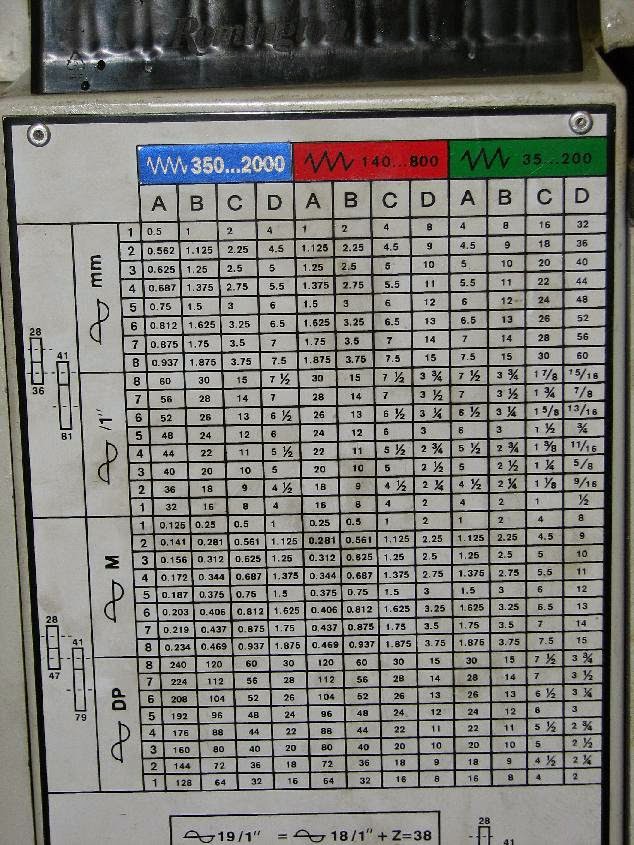

How to use threading chart on this lathe? Acra 1440TE r/Machinists

Thread Cutting Procedure of Lathe Machine: Now discussing about the thread cutting on a lathe machine. To cut thread first thing is to calculate the pitch, lead, major diameter, minor diameter and depth. To cut thread, a single point cutting tool used is a turning tool with a carbide insert. Now follow the following steps: -

Lathe Thread Cutting Chart Depth of Compound for SAE Threads 3" eBay

3. Mark and rough the material: Use a center punch to mark the position of the threads, and rough the material to the desired diameter using a facing tool. 4. Set the threading tool: Mount the threading tool into the tool post of the lathe, ensuring that it is square to the workpiece and set to the correct height. 5.

Lathe Thread Cutting Chart Depth of Compound for SAE Threads 3" eBay

Thread cutting tool. Internal thread cutting tool. Facing tool. Grooving tool. Forming tool. Boring tool. Parting-off tool. Counterboring tool Undercutting tool According to the method of applying feed Right-hand tool Left-hand tool Round Nose Lathe Cutting Tools Based on the Material Used

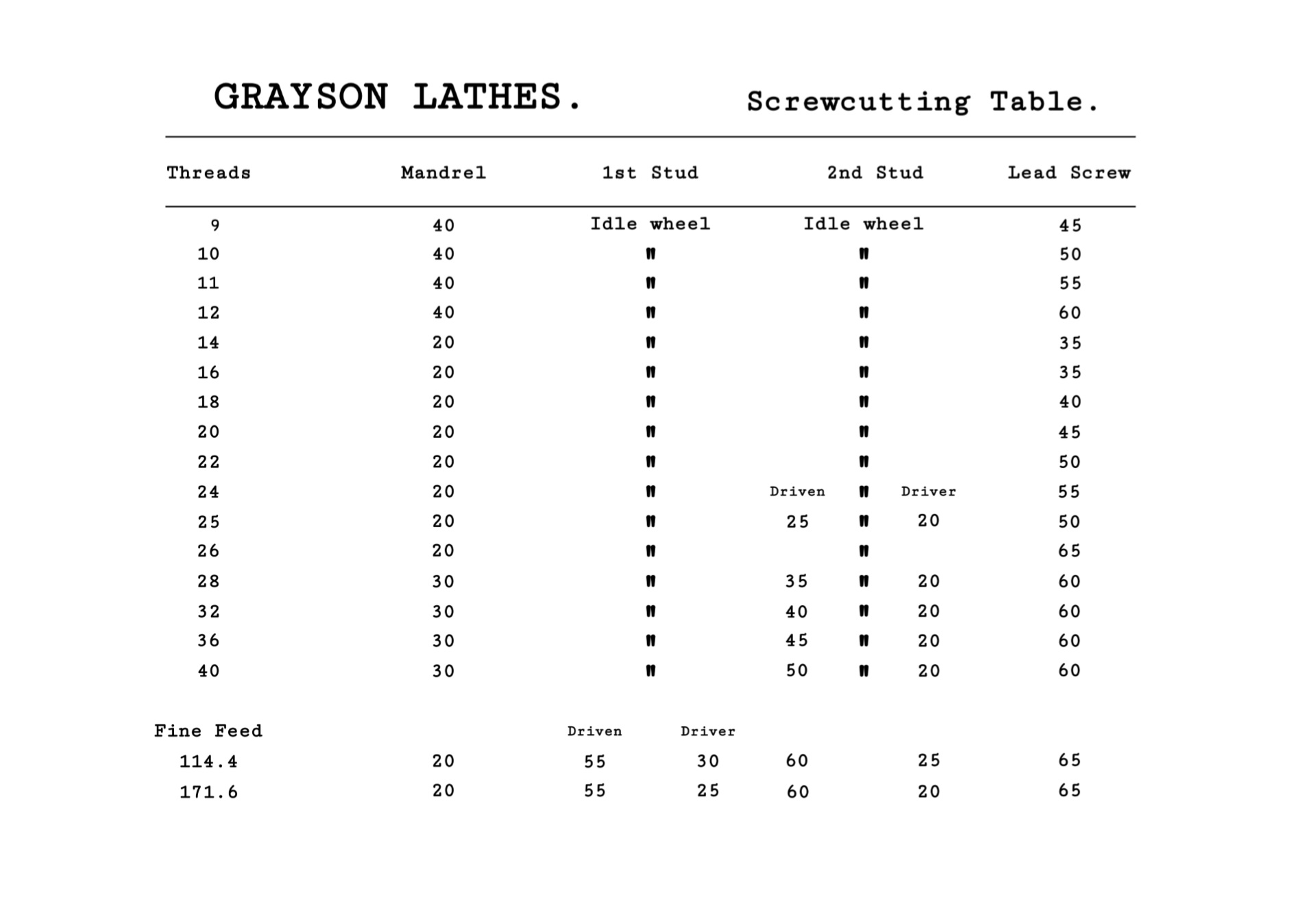

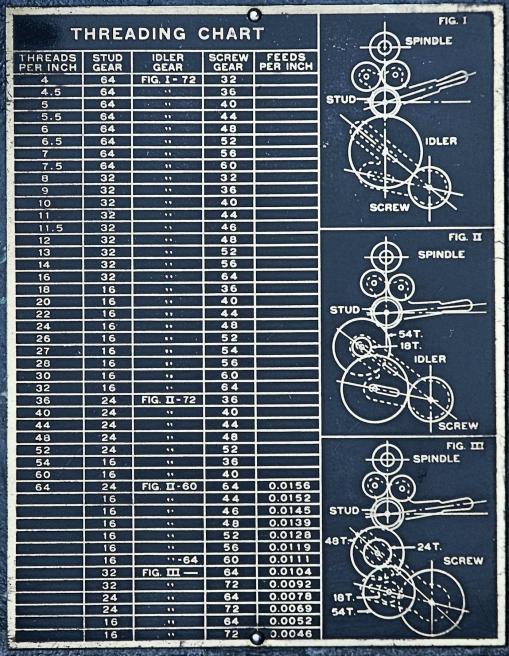

Help needed with screw cutting charts on lathe Model Engineer

How to Cut Threads on a Lathe? So, if you are interested and want to know how to cut threads on a lathe, then keep reading, and you will know the easy thread cutting methods. Four infeed methods can be used for cutting threads on a lathe. They are listed below: Flank infeed

Machining Turning thread on a Lathe

#1 Thread chart help on lathe. 11-12-2014, 02:43 PM This is my threading chart. I have most of it figured out (i generally use a die) but.. need some help. I was looking to cut some 1.125-8 yesterday and ran into a question.. At the top, where it show threads..what does the symbols mean? Such as 1/n" or what looks to be PI/DP".?? Thanks

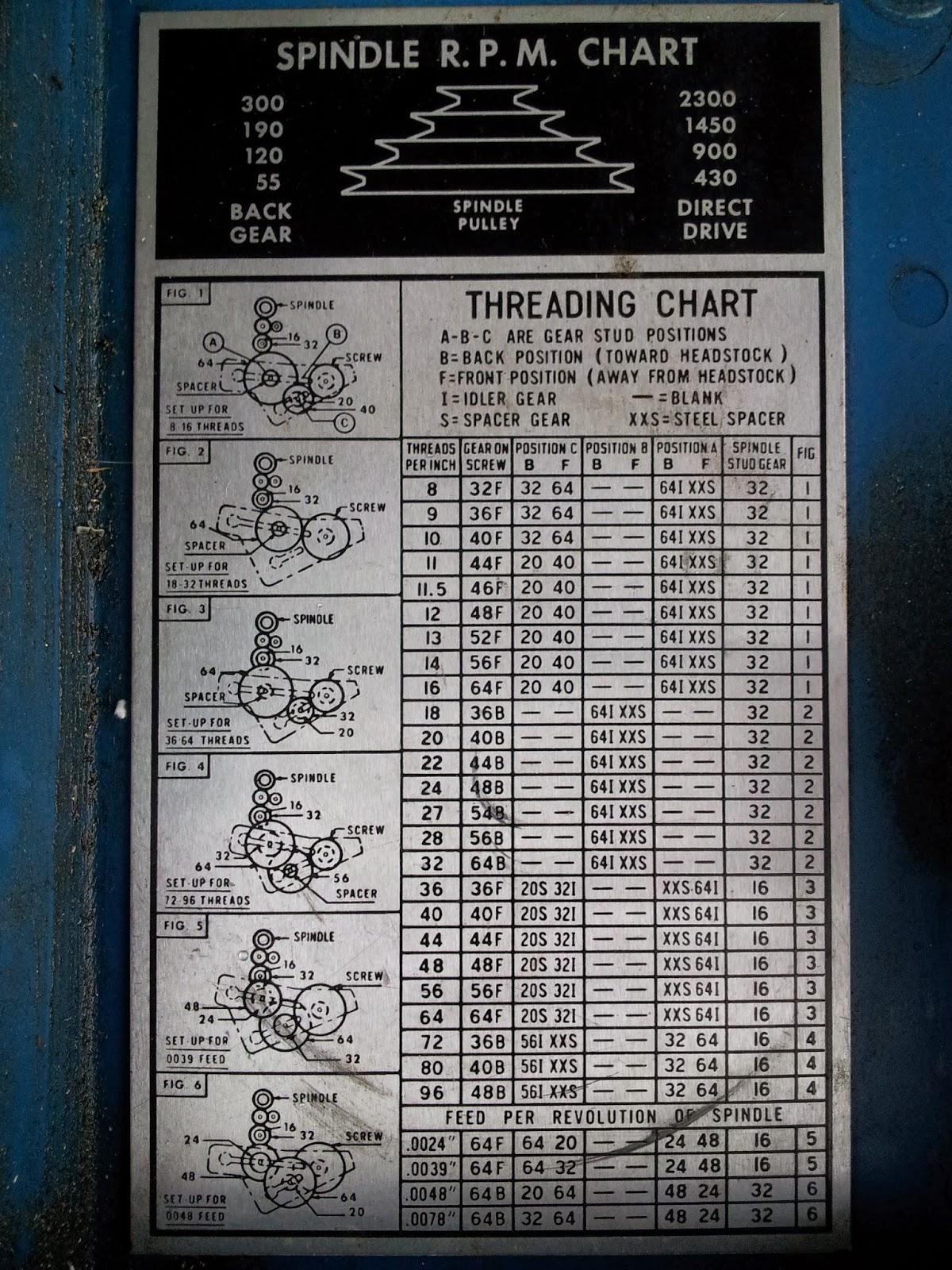

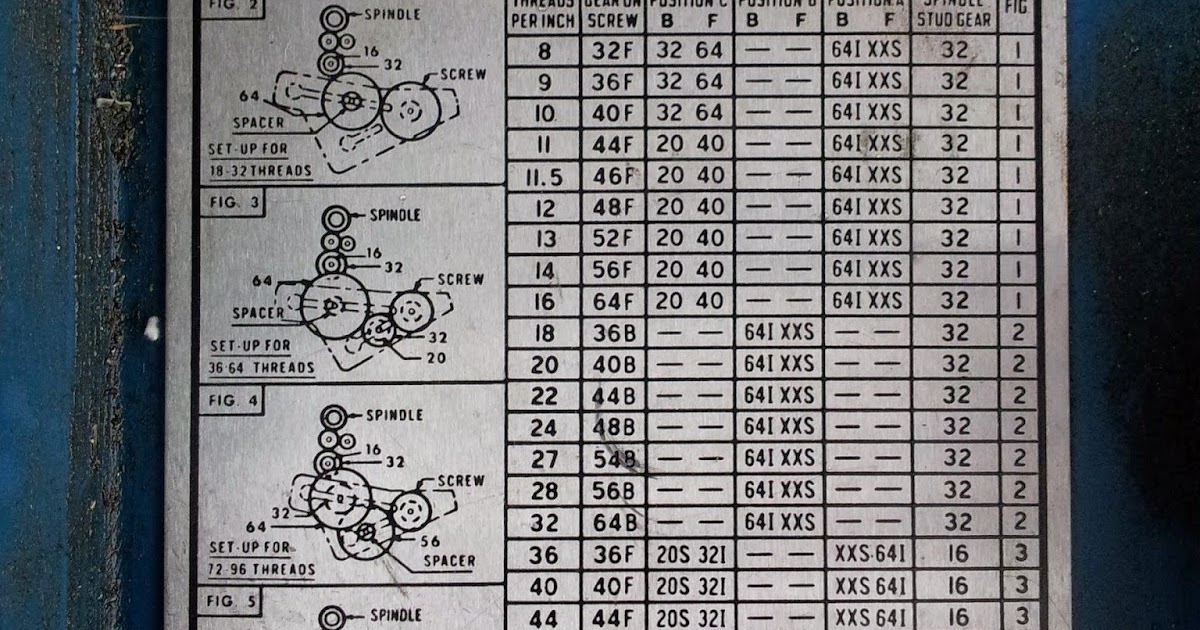

"Pay it Forward" technology blog Atlas Clausing 6 inch metal turning lathe model 10100 information

Threading On A Lathe The right choices in tooling and technique can optimize the thread turning process. #Basics Stuart Palmer Photo Credit: Getty Images Tools for turning threads have benefited from the same improvements in coatings and material grades that have improved turning tools overall.

Logan 200 gear arangement

Guides Lathe How to cut threads on a lathe How do you cut threads on a lathe? Start by the workpiece as you machine it to the diameter of the thread cut using the turning center. Place the workpiece in a chuck for threading between centers. The chuck connects to the spindle, engaged with the lead screw.

Cutting Metric Threads on a Plain Change Logan Lathe

Threads with small profile angles. ALP = Radial clearance. ALF = Flank clearance. For ACME, trapezoidal, and rounded threads, it is especially important to choose the correct shim to tilt the insert, because the pressure on the cutting edge is higher, and the flank clearance is smaller. Flank clearance (ALF) depends on profile.

7) thread cutting on a lathe machine Download Scientific Diagram

#1 Hello all, I've been a hobbiest for several years now. I have a Bridgeport mill series II and a Taiwan Enco lathe model 92010 from 1982. Lately I've decided to try my hand at single point threading. I've watched countless videos and read many posts on how to do it but of course my threads don't come out correctly.

Help me to understand Lathe chart and threading

By dividing the full cutting depth of the thread into smaller cuts, the sensitive nose radius of the insert is not overloaded. Example: By taking 0.23-0.10 mm (0.009-0.004 inch) in cutting depth per pass (radial infeed), the full cutting depth ( a p ) and the profile depth of the thread (0.94 mm (0.037 inch)) are turned on a 1.5 mm (0.06.

Lathe change wheels Model Engineer

These are gear setups to cut Metric Threads on Logan and Montgomery Wards Lathes WITHOUT a Quick Change Gearbox. These charts SHOULD work with other Lathes that have the same ratios as the Logans. The key factors are: 1:1 ratio from Spindle to Stud Gear 8 TPI Lead Screw

Lathe Thread Chart Wm250 chickspowen

9.4K 1.1M views 3 years ago ENGLAND How to cut threads on a lathe is a fundamental skill of any machine operator. This is an intermediate method that is ideal for most applications and lends.